Description

ALERT - QTY 20 Minimum Order Amount

How To Choose

Find your insulated curing blanket

Answer a few quick questions. We will suggest the best R-value and specific blankets that fit your job.

Guidance uses independent R-value testing (ASTM C-518 or C-236 procedures). Real-world performance varies with wind sealing and moisture control. For very low temps, stacking two blankets increases total thermal resistance.

Specifications

| ALCO Part # | DESCRIPTION | R-Value | Layers | Color (Top/Bottom) |

|---|---|---|---|---|

| CC-6x25-R2.2 | 6' X 25' BUBBLE MEDIA CURING BLANKET | R 2.2 | 2-Layer Bubble | Black/Black |

| CC-12x25-R2.2 | 12' X 25' BUBBLE MEDIA CURING BLANKET | R 2.2 | 2-Layer Bubble | Black/Black |

| CC-6x25-R3.0 | 6' X 25' BUBBLE MEDIA CURING BLANKET | R 3.0 | 3-Layer Bubble | Black/Black |

| CC-12x25-R3.0 | 12' X 25' BUBBLE MEDIA CURING BLANKET | R 3.0 | 3-Layer Bubble | Black/Black |

| CC-6x25-R2.5 | 6' X 25' FOAM MEDIA CURING BLANKET | R 2.5 | 4-Layer Foam | Black/Black |

| CC-12x25-R2.5 | 12' X 25' FOAM MEDIA CURING BLANKET | R 2.5 | 4-Layer Foam | Black/Black |

| CC-6x25-R2.8-BB | 6' X 25' FOAM MEDIA CURING BLANKET | R 2.8 | 6-Layer Foam | Black/Black |

| CC-12x25-R2.8-BB | 12' X 25' FOAM MEDIA CURING BLANKET | R 2.8 | 6-Layer Foam | Black/Black |

| CC-6x25-R1.84 | 6' X 25' FOAM MEDIA CURING BLANKET | R 1.84 | 2-Layer Foam | Black/Black |

| CC-12x25-R1.84 | 12' X 25' FOAM MEDIA CURING BLANKET | R 1.84 | 2-Layer Foam | Black/Black |

| CC-6x25-R2.11 | 6' X 25' FOAM MEDIA CURING BLANKET | R 2.11 | 3-Layer Foam | Black/Black |

| CC-12x25-R2.11 | 12' X 25' FOAM MEDIA CURING BLANKET | R 2.11 | 3-Layer Foam | Black/Black |

| ALCO Part # | DESCRIPTION | R-Value | Layers | Color (Top/Bottom) |

|---|---|---|---|---|

| CC-6x25-R2.8 | 6' X 25' BUBBLE MEDIA CURING BLANKET | R 2.8 | 2-Layer Bubble | Black/Metal |

| CC-12x25-R2.8 | 12' X 25' BUBBLE MEDIA CURING BLANKET | R 2.8 | 2-Layer Bubble | Black/Metal |

| CC-6x25-R5.11 | 6' X 25' FOAM MEDIA CURING BLANKET | R 5.11 | 6-Layer Foam | Black/Metal |

| CC-12x25-R5.11 | 12' X 25' FOAM MEDIA CURING BLANKET | R 5.11 | 6-Layer Foam | Black/Metal |

| CC-6x25-R5.11-CB | 6' X 25' COMBO MEDIA CURING BLANKET | R 5.11 | 2-Layer Bubble + 1-Layer Foam | Black/Metal |

| CC-12x25-R5.11-CB | 12' X 25' COMBO MEDIA CURING BLANKET | R 5.11 | 2-Layer Bubble + 1-Layer Foam | Black/Metal |

| CC-6x25-R5.61 | 6' X 25' FOAM MEDIA CURING BLANKET | R 5.61 | 4-Layer Foam | Black/Metal - Black Metal |

| CC-12x25-R5.61 | 12' X 25' FOAM MEDIA CURING BLANKET | R 5.61 | 4-Layer Foam | Black/Metal |

| CC-6x25-R6.1 | 6' X 25' BUBBLE MEDIA CURING BLANKET | R 6.1 | 3-Layer Bubble | Black/Metal |

| CC-12x25-R6.1 | 12' X 25' BUBBLE MEDIA CURING BLANKET | R 6.1 | 3-Layer Bubble | Black/Metal |

| CC-6x25-R6.32 | 6' X 25' FOAM MEDIA CURING BLANKET | R 6.32 | 8-Layer Foam | Black/Metal |

| CC-12x25-R6.32 | 12' X 25' FOAM MEDIA CURING BLANKET | R 6.32 | 8-Layer Foam | Black/Metal |

| CC-6x25-R7.74 | 6' X 25' BUBBLE MEDIA CURING BLANKET | R 7.74 | 2-Layer Bubble | Black/Metal - Metal |

| CC-12x25-R7.74 | 12' X 25' BUBBLE MEDIA CURING BLANKET | R 7.74 | 2-Layer Bubble | Black/Metal - Metal |

The Industry Standard

Insulated Concrete Blankets by ALCO provide insulation when and where contractors need it. The winter elements shall not stop your next construction project. These foam-insulated, double-stitched, and UV-resistant blankets are the industry standard that contractors reply on. Can be used vertically or as ground cover. Some common applications include:

- Concrete curing blanket

- Temporary curtain wall

- Insulated enclosure

- Scaffolding enclosure

- Ground Cover

- Temporary heat enclosure

Key Features

Details and Key Benefits

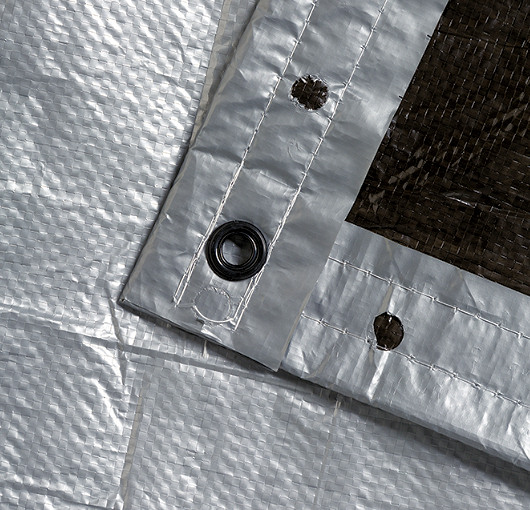

- 8×8 weave poly tarp with layered closed cell PE foam core

- Industrial grommets every 24" around all edges for easy install

- All finished stitched edges for clean look

- Designed to hold up in extreme low temperatures

- Resistant to sunlight, moisture and mildew.

- The core stays dry, allowing the insulated tarp to control the temperature

- Color: Silver and Black or all Black

- FR Rating: Non-fire retardant

- Material: 100% reusable

Serving The Industry Leaders

How to choose the right insulated curing blanket

1) Pick your SERIES

Reflective “M Series” (Black/Metal skins)

-

Best when you want to trap as much heat as possible.

-

Ideal for exposed slabs, windy sites, and when daytime sun can help.

-

Place the metal side toward the concrete to reflect radiant heat back into the slab.

Non-Reflective “N Series” (Black/Black skins)

-

Low-glare, great value, and rugged.

-

Ideal for typical shoulder-season pours, residential sites, or where reflectivity is not desired.

2) Choose an R-VALUE for your weather

Use your expected overnight low and bump up one tier for strong wind, shaded sites, or multi-day cures.

-

35–45 °F nights: R1.8 to R2.5

-

25–35 °F nights: R2.8 to R3.4

-

10–25 °F nights: R5.1 to R5.6

-

Below 10 °F or long cure: R6.0+ or double-layer two blankets

Notes

-

Stacking blankets increases total thermal resistance and improves results.

-

Edge sealing matters as much as R-value. Prevent wind from getting under the blankets.

3) Pick a CORE that fits how you work

Bubble cores

-

Light and quick to deploy.

-

Great for daily pours and frequent moves.

Foam cores

-

Higher, steadier R-value and better crush resistance under foot traffic.

-

Good for colder jobs and repeat use.

Hybrid bubble + foam

-

Best balance of weight and performance.

4) Pick a SIZE and plan your coverage

-

6×25 ft covers 150 sq ft.

-

12×25 ft covers 300 sq ft.

-

Plan 3–6 in overlaps between blankets. Offset seams if you stack layers.

Quick picks

-

Budget curing near freezing: N Series R2.2 to R3.4.

-

All-around cold weather: M Series R5.11 or R5.61 for 10–30 °F nights.

-

Severe cold, ground thaw, or multi-day cures: M Series R6.1, R6.32, or R7.74, or double-layer two blankets.

Best practice tips

-

Cover immediately after finishing to hold moisture and temperature.

-

Keep edges weighted or taped to stop air infiltration.

-

Do not use open flame under the blankets.

-

Remove gradually to avoid thermal shock, especially in very cold weather.

R-values are from independent testing following ASTM C-518 or ASTM C-236 procedures. Actual performance varies with site conditions. For structural guidance, refer to ACI 306 cold-weather concreting practices.