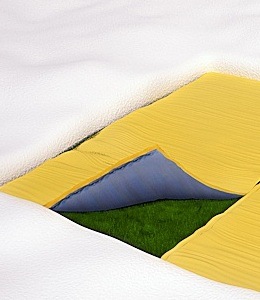

OVERVIEW On an annual basis, the construction industry has to deal with frozen ground. The problem costs time, efforts, and money to fix. Frozen ground can be costly for some contractors because it delays projects and creates safety hazards for workers. Without proper knowledge, prep work might take longer than the project job itself. Delaying […]

Read MoreWhy Insulated Concrete Curing Blankets? ALCO Covers offers one-time usage and reusable wet concrete curing blankets depending on what you need. As endorsed by the American Concrete Institute (ACI), these products conserve ideal moisture content during the concrete curing process. Cracking, Dusting, Scaling and crazing on curing process are caused due to the absence or […]

Read MoreIn a planned project, one’s patience is tested when waiting for the curing of concrete. It takes a lot of time, and it’s also necessary especially when it is time to move to the next sequence of the project. ALCO Electric Concrete Curing Blankets can help expedite the sequence However, the idle point purpose of […]

Read MoreWhat is the Temperature for Concrete Curing? The standard temperature to achieve full strength in concrete curing is 55°F. this is regardless the weather condition. Dam Curing The Hoover dam as you know was the largest dam worldwide at its completion. June 6, 1933, was a remarkable day for engineers on the site as they […]

Read MoreWhat Is The Setting Time For Concrete? The truth is concrete curing is a continuous process, it hardens steadily forever. But practically speaking, concrete curing reaches a point, which is after a couple of weeks, where hardening will become too slow and invisible. Does Concrete Stop Curing? The reason behind its continuous hardening is due […]

Read MoreWhat Temperature Is Too Cold For Concrete Curing? Studies and Research have shown that the best temperature to pour concrete is 55°F. The mixing of cement and moisture bonds steadily to give concrete its full strength and the temperature is always at 55°F. This bonding is continuous and not observable below 40°F. During daytime when […]

Read More