What Temperature Is Too Cold For Concrete Curing? Studies and Research have shown that the best temperature to pour concrete is 55°F. The mixing of cement and moisture bonds steadily to give concrete its full strength and the temperature is always at 55°F. This bonding is continuous and not observable below 40°F. During daytime when […]

Read MoreTemperature for Concrete Curing For concrete to achieve full strength, it is believed that the standard temperature for curing is 55°F. Weather condition does not determine this standard temperature. How The Hoover Dam Curing Was Accomplished One of the largest dam worldwide after it was completed was the hoover dam. On June 6, 1993, was […]

Read MoreWhen is Setting Curing Time For Concrete? One thing you should know about curing is that it is an endless process that hardens always to infinity. Although, it gets to a point when hardening becomes too slow to observe and concrete can be placed and used without it cracking. This is normally few weeks after […]

Read MoreWhen is Temperature Too Cold For Concrete Curing? According to research the perfect temperature to pour concrete to attain full strength is 55°F. The steady mix of cement and moisture forms bond which gives concrete its full strength, this steady forming of bonds is continuous and not observable in concrete, the temperature at this time […]

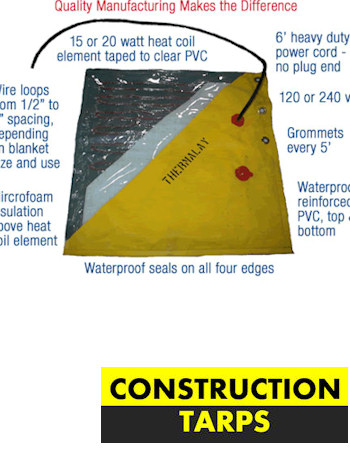

Read MoreConcrete Curing Blankets Snow and ice have covered the surface of the ground after a long period of snowstorm restricting movement and work. Getting back to a concrete job is difficult at his period due to the snow build up, heat is needed to help melt ice away and work can resume. Electric Curing blankets ground […]

Read MoreWhat is curing? Maintaining a suitable moisture content and temperature in concrete at early ages so that it will progress properties the mixture was created to accomplish is otherwise known as curing. Generally, curing takes place once the concrete has been placed and finished so that the concrete will develop to the desired strength and […]

Read More